CNC Plasma cutting machines are a great way to improve the efficiency and quality of your metalwork but sometimes things can go wrong. While there are many benefits of using a CNC plasma cutter, you’ll also want to avoid any mistakes or inefficiencies.

In this article, we share 7 common CNC plasma-cutting mistakes and how to avoid them. Whether you’re new to CNC plasma cutting or a seasoned professional, these tips will ensure your processes are as efficient and precise as possible.

1. Poor grounding practices

If you experience erratic motor movement, sensors triggering randomly, or software disconnecting from the controller, your machine setup may need to be adjusted. These random communication errors often happen when the machine is not earthed properly, or in some cases, nearby equipment may be interfering.

Solutions

To reduce communication errors, implement proper earthing practices as recommended by the plasma source manufacturer. We also require the use of an earth stake on our XT table range, but it is highly recommended for any CNC Plasma setup. This will ensure all electrical connections are safe and consistent, minimising communication issues while you work. You’ll also need to make sure equipment nearby such as generators, high-frequency TIG welders, and other machinery are not interfering with the plasma cutter.

2. Incorrect cut settings

Using the wrong torch cutting height or cutting speed, etc., may lead to poor cut quality and short consumable life. In many cases, the torch may also hit the workpiece while you work. If you notice a lot of edge bevel angle and dross, it is likely that your settings are not correct.

Solution

Fortunately, these problems can be avoided with good Torch Height Control (THC) and correct operator techniques. Always double-check the manufacturer’s recommendations and make sure your settings are appropriate for the material you want to cut.

3. Insufficient airflow

If the air pressure is set incorrectly on your plasma cutter, you will experience poor cut quality and dross build-up. This occurs when the plasma requirement matches or exceeds the compressor’s capacity.

Solution

To correctly set air pressure, check the manufacturer’s specifications and ensure the compressor’s capacity comfortably exceeds the plasma’s requirement.

4. Insufficient power supply

If your power supply is inadequate for your plasma cutter, it may result in poor cut quality, inefficient cutting speeds, and machine malfunctions. With insufficient power, your machine may be prone to incomplete cuts or unexpected stoppages when the breaker is tripped.

Solution

If you already have a plasma cutter, consider upgrading the power supply. Or, if you are purchasing a new plasma cutter, ask our team which machine is best suited to your power supply.

5. Cheap CNC plasma cutter software

One of the most common mistakes we’ve seen in the industry is opting for cheap, poorly designed CNC software. Some manufacturers cut corners when developing their software, making them inefficient and difficult to use. This will impact your workshop’s output, ultimately costing you more in the long run.

Solution

To make the most of your plasma cutting, choose reliable software like SURECONTROL. We developed this software for ease of use and exceptional accuracy, maximising your performance and cut quality.

6. Undersized plasma-cutting machines

When investing in a plasma cutter, many businesses choose a smaller machine to match their current demand. While this may be enough for a while, it will limit the growth of your business and restrict the projects you can work on. When a larger project arises, you’ll have to turn it down or invest even more resources in another machine.

Solution

We recommend choosing a larger plasma cutting model than you currently need. This allows you to adapt to each new project and prepare for business expansion. When those opportunities arise, you can say yes without hesitation. For more information on how to choose the right CNC plasma cutter, read this article.

7. Incorrect CNC Plasma Cutter torch consumables

Using the wrong nozzles, torches, and spare parts may cause poor cut quality and shorten the lifespan of your machine’s parts. Another common symptom is that the torch will hit the workpiece repeatedly, causing frustrating disruptions and affecting the accuracy of each cut. Failing to use genuine parts may also result in a voided warranty.

Solution

To resolve this common problem, make sure your torch consumables are correct for the material you want to cut and the machine you are using.

At Surefire CNC, our parts and consumables are compatible with a range of plasma-cutting machines, including the SYNC, Duramax, Hyamp, and MaxPro series. We keep large stocks and ship anywhere in Australia, providing genuine spare parts and accessories like CNC water bed fluid, air filters, and more.

Browse our parts and consumables >>

Plasma cutting machines

At Surefire CNC, we believe well-designed CNC Plasma Cutters can be cost-effective and easy to use. That’s why we own the entire production process of our plasma machines, including design, engineering, manufacturing, supply, and servicing. This means you can enjoy a machine that is reliable, well-built, user-friendly, and affordable.

KT Series

Our KT Series is designed for smaller workshops and hobbyists, with easy operation, Australian-based technical support, and the option to expand later.

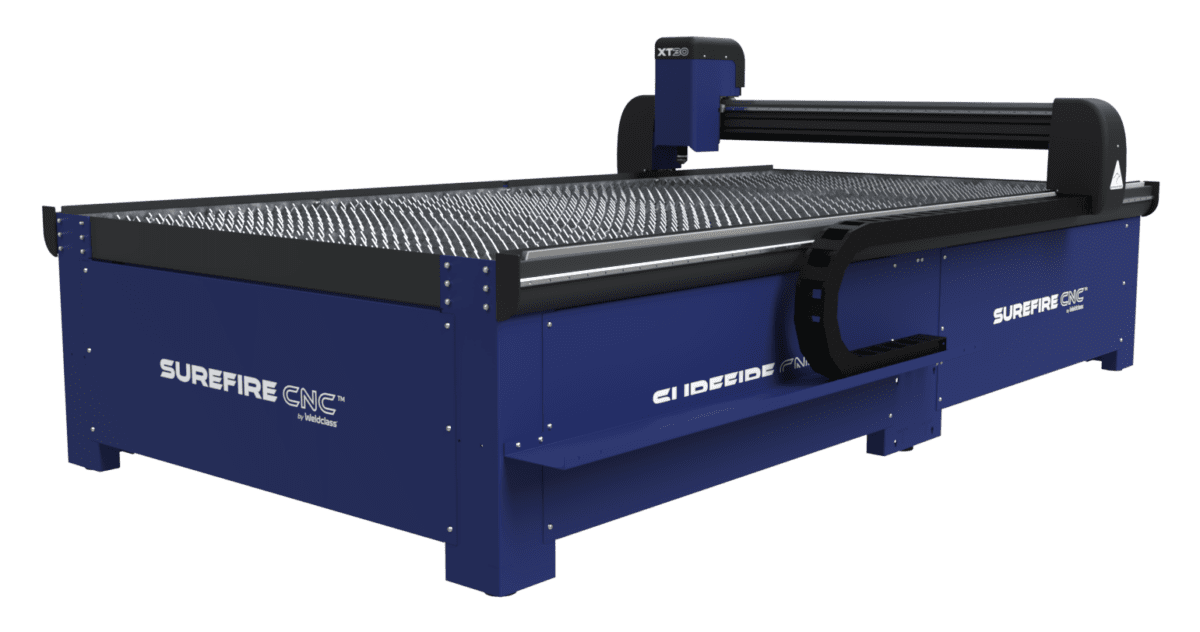

XT Series

Our XT Series is engineered for industrial applications, with easy operation, exceptional durability, and Australian-based technical support.

If you aren’t sure which plasma cutter is right for your application, try our Product Selector tool. With a few simple questions about your projects, we’ll show you the best model for your workshop. Alternatively, contact our team of experts today to discuss your requirements.

Related Posts

CNC plasma cutting is a fast, precise, and efficient cutting method. While it is straightforward and efficient to use, it…

If you need an accurate cutting machine for metalwork, you might be considering a CNC plasma cutter. And, while there…

Finding the ideal CNC plasma cutter for your specific needs can be difficult. When navigating the market, you may become…

Work with us today

For more information on our products, services, and solutions, and to get pricing, please click on the button below.