AUSTRALIA’S CNC PLASMA CUTTER SPECIALISTS

WE LIVE & BREATHE CNC PLASMA

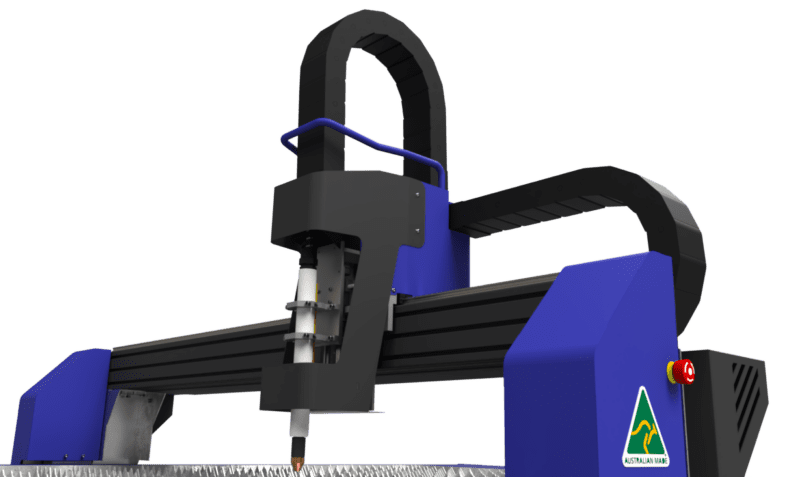

ENGINEERED AND MANUFACTURED IN AUSTRALIA

IT’S NOT WHAT IT COSTS, IT’S HOW MUCH IT MAKES

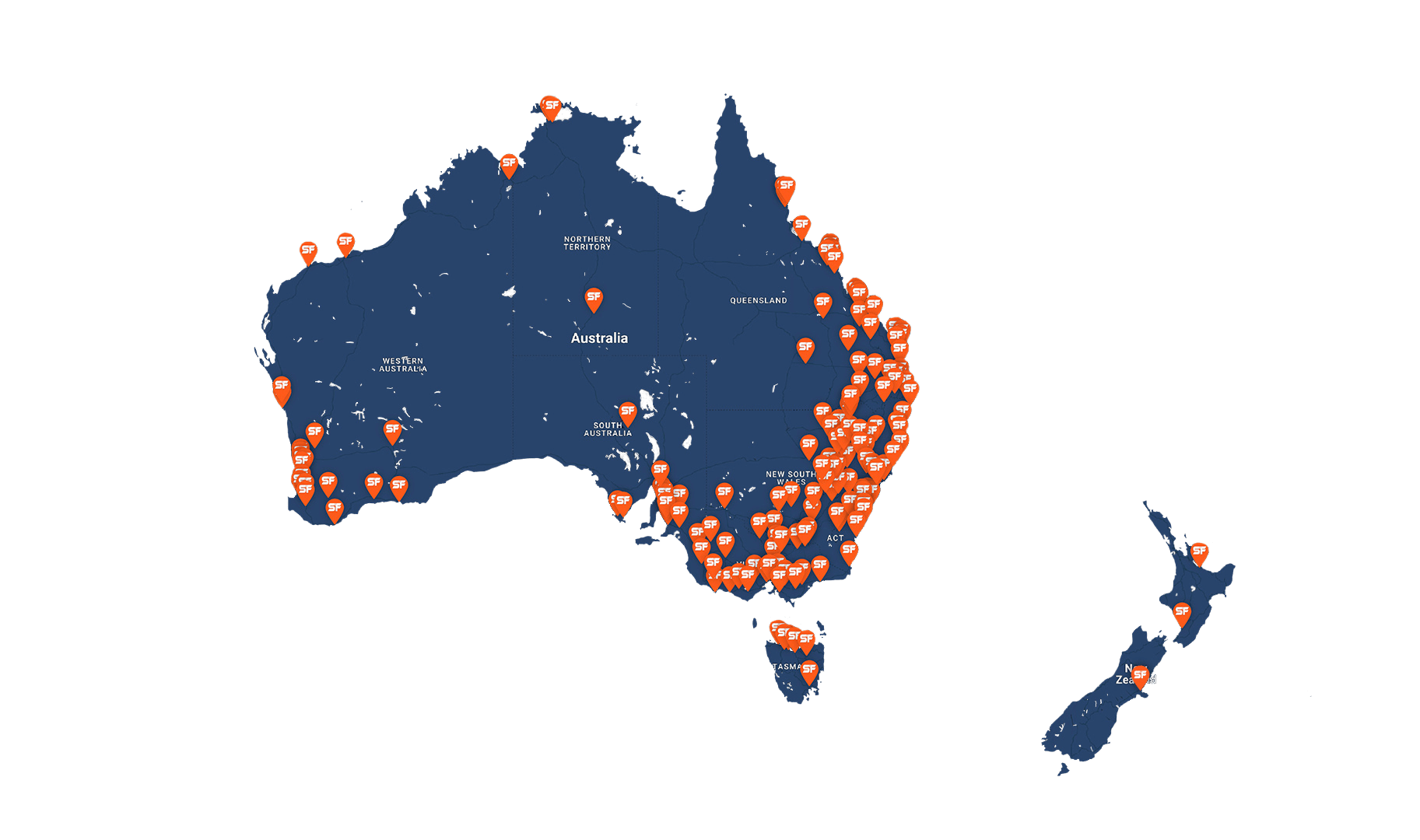

We firmly believe that Australian manufacturing is right up there with the best. And that’s why our range of CNC Plasma Cutters are designed and made right here in Australia.

In addition, SUREFIRE CNC partners with other leading manufacturers globally – such as Hypertherm plasma cutters, to develop CNC equipment solutions that deliver what Aussie fabricators are looking for.

Plasma will cut any electrically-conductive materials, including steel, stainless-steel, aluminium and most metals. CNC plasma tables are used for a wide range of metalfab applications where versatility is critical, such as fabrication shops, manufacturing, automotive repair and restoration, training centres, and more.

In short, a plasma table is the main component in a CNC plasma system used for cutting shapes from flat sheets of steel or metal. To perform this task, a plasma table must be coupled with other machinery. The main components of a CNC plasma table system and their functions are as follows;

CNC Plasma tables are used in metal fabrication and manufacturing industries for cutting components from flat metal sheet or plate, including steel, stainless-steel, aluminium & other metals.

This depends on a few factors. First the design of the table; XT Series plasma tables are accurate to within 0.2mm, thanks to the direct rack & pinion drive mechanism. Next is the accuracy of the plasma arc, which will vary depending on the quality and condition of the plasma system, torch and consumable parts. We recommend allowing between 0.5-1.0mm for plasma arc deviation, noting that worn consumables and poor air quality will result in higher deviation. One of the reasons we use Hypertherm plasma machines is because they offer unmatched performance, accuracy and parts durability.

Great question! Each system has their place. For general metalfab applications with materials of up between 1mm & 30mm thickness, CNC Plasma offers the best combination of affordability, fast cutting (productivity), low running costs and versatility. For more information on this topic, visit our blog Plasma vs Waterjet vs Laser vs Oxy | How Economical is CNC Plasma?