If the plasma or table stops, you may need to restart the cut halfway through the program. Note before you start this make sure you have the latest version of our control software available here: https://surefirecnc.com/knowledge-base/updating-mach3/

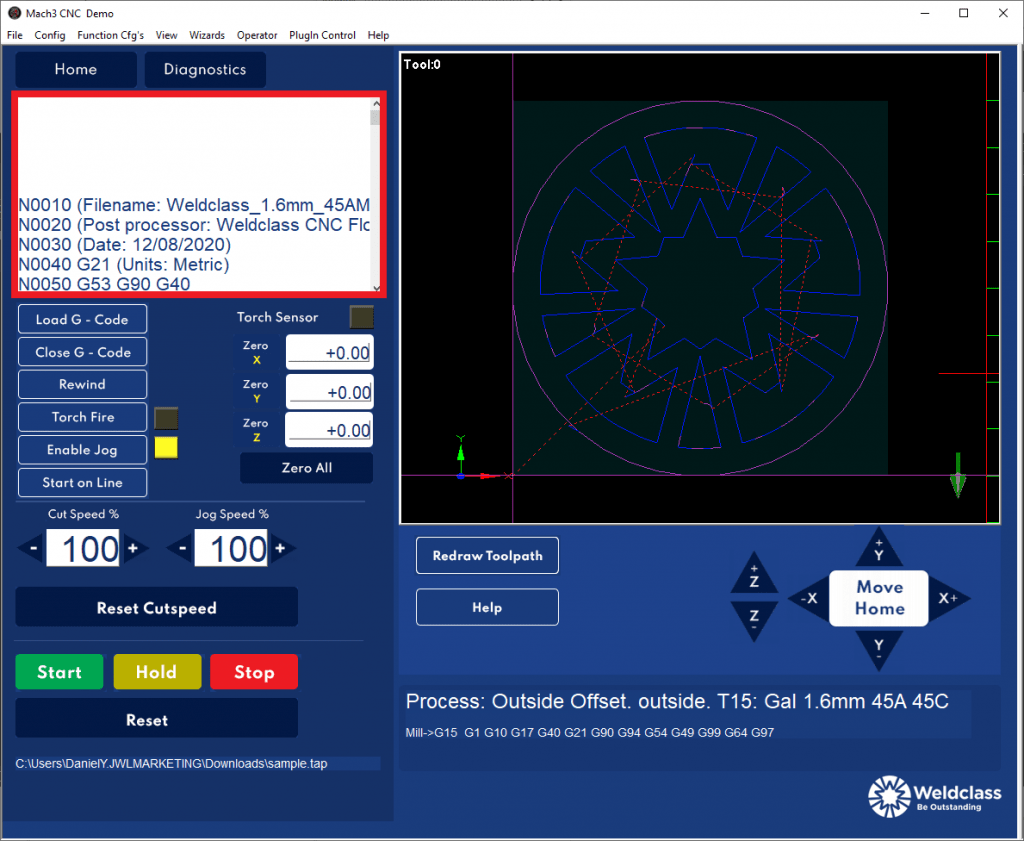

1. Click in the G-Code window on the top left of the screen.

2. As you scroll through the code the preview window on the right-hand side will update showing where it is up too. Find the point at which the machine stopped.

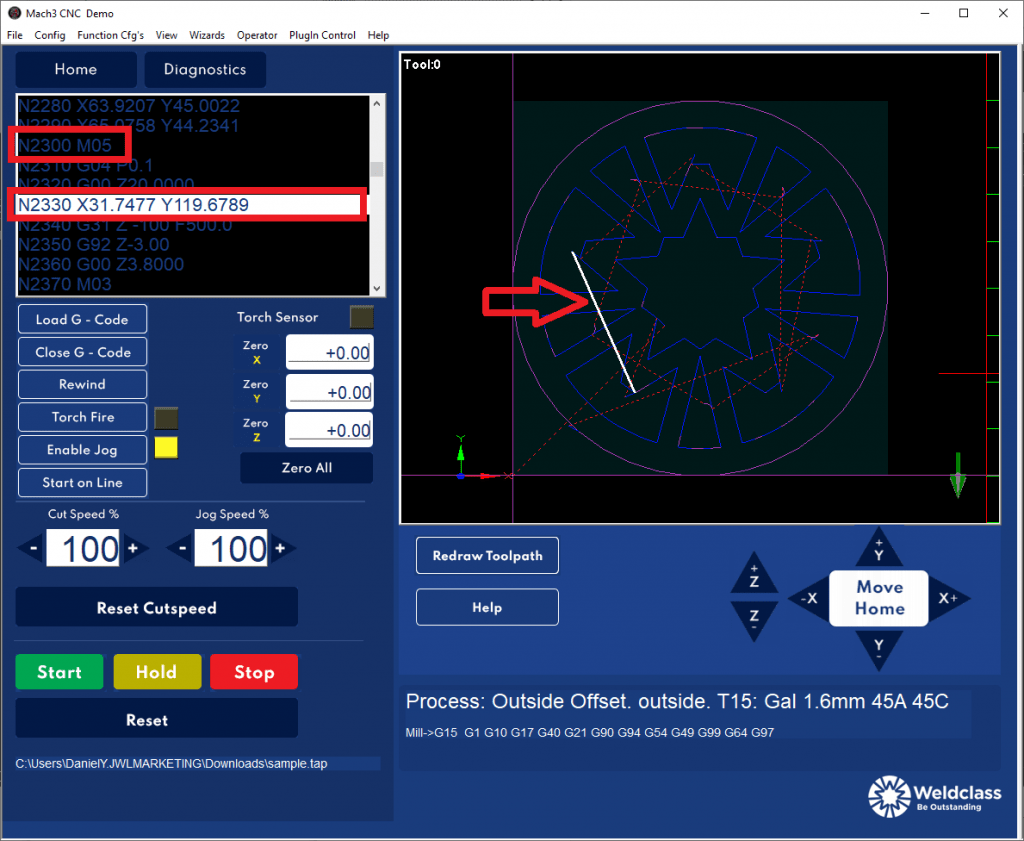

3. Scroll back up to the last torch off point. The code will be ‘M05’ as below:

In the example below, the plasma stopped on Line N2330, which is the highlighted line to the right. We scroll back up to highlight line N2300, shown in the next image.

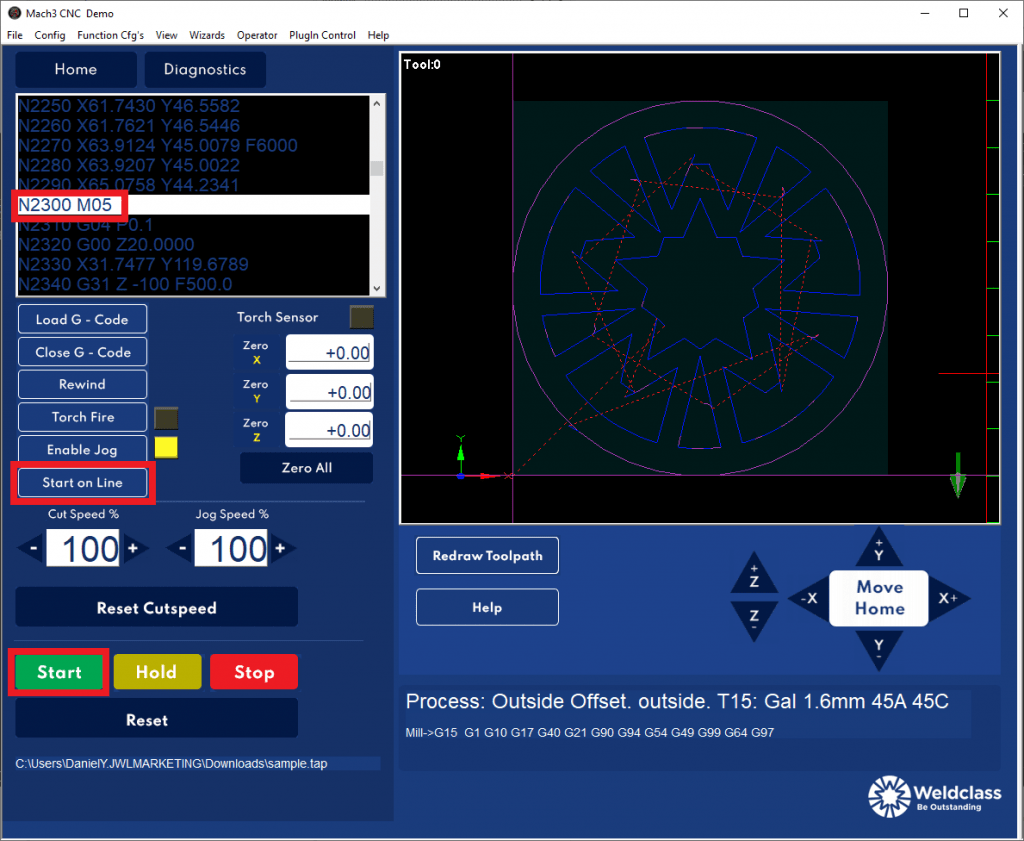

4. Click Start on Line, then click Start.

5. Note that if the machine has stopped in the middle of a cut, it will redo the start of that cut again. To avoid this, we can turn the plasma off and allow it to dry cut until the head moves closer to the fault point. We then turn on the plasma and click ‘Torch Fire’ as it passes the point.

Related Posts

In Mach3 next to the ‘file’ tab in the top left of the window, select ‘Config,’ then select ‘General Config.’…

Skilled operators and well-maintained plasma arc cutting (PAC) equipment are essential for maximizing efficiency and minimizing costs in any cutting…

Hypertherm plasma cutters are known for their high quality cuts. However, there are a few common problems that can occur…

Work with us today

For more information on our products, services, and solutions, and to get pricing, please click on the button below.