TEST 1:

Turn off the power

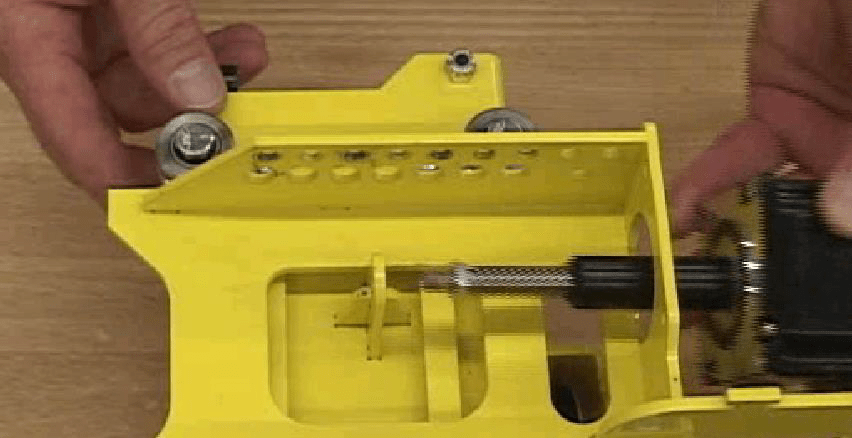

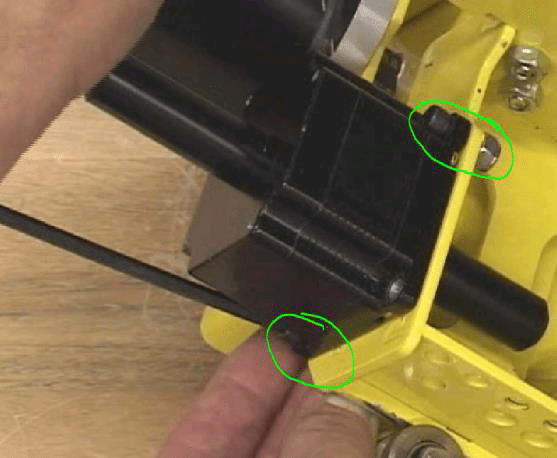

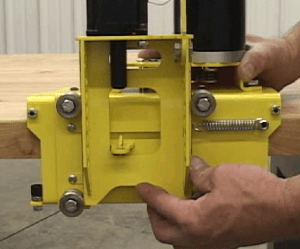

Remove the Z-axis motor.

Loosely reattach just the motor body using two opposite bolts.

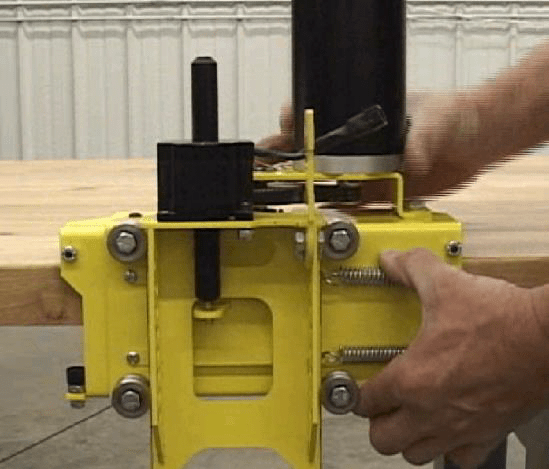

Hold the carriage vertically on the edge of a table.

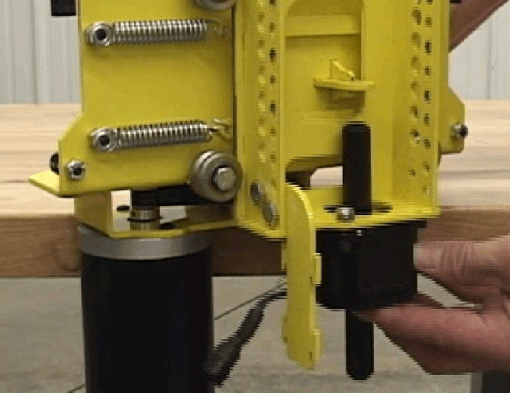

Lift the holder back to the top of its travel and then slowly lower it under just its own weight. Do this a few times, then turn the carriage upside down and repeat the motion a few more times.

SUMMARY:

If the Z-axis moves smoothly without getting stuck, then the problem is in the motor, wiring harnesses, or controller. Proceed to ‘TEST 2’ below.

If the Z-axis moves roughly or gets stuck, then the problem is in the holder back and wheels. Refer to the video manual to troubleshoot the mechanical movement.

TEST 2

Check the Z-axis motor windings and the two wiring harnesses connecting the motor to the controller, replacing any faulty component found. Otherwise, replace the Z-axis motor.

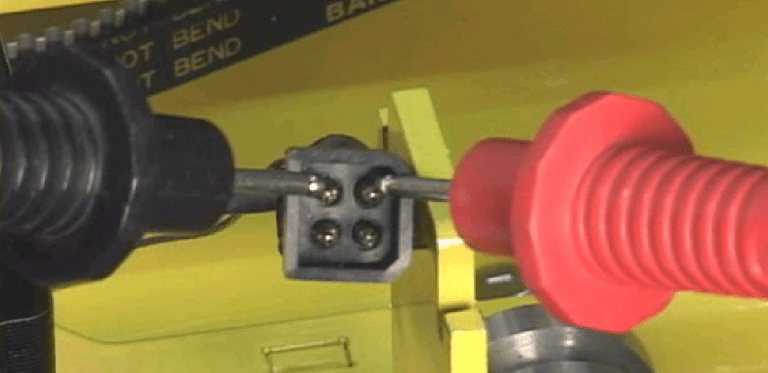

Measure the motor resistance through various pairs of terminals on the motor connector. The resistance between these terminals should measure between 320 and 390 ohms.

The resistance between these terminals should measure between 320 and 390 ohms.

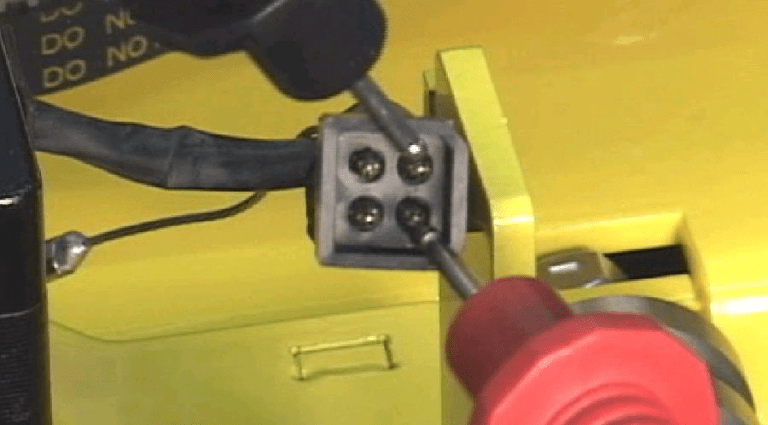

The resistance between these terminals should measure between 640 and 780 ohms.

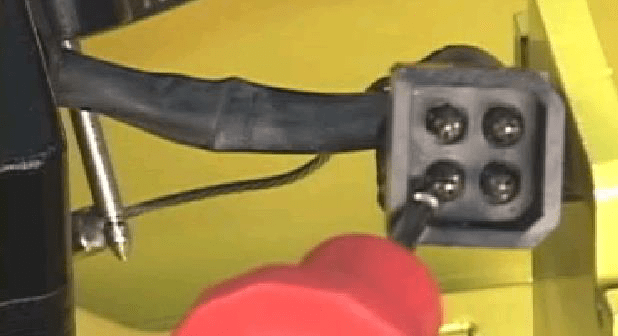

Verify isolation between these two terminals.

Verify continuity between this terminal and the ground terminal bolted to the motor.

SUMMARY:

If the winding resistance, isolation or continuity tests ever fail to measure correctly, the Z-axis motor is faulty and should be replaced.

If these tests don’t find any fault, check the two wiring harnesses connecting the motor to the controller, replacing any faulty component found. Otherwise, replace the Z-axis motor or if the problem persists, replace the controller.

Related Posts

In Mach3 next to the ‘file’ tab in the top left of the window, select ‘Config,’ then select ‘General Config.’…

Skilled operators and well-maintained plasma arc cutting (PAC) equipment are essential for maximizing efficiency and minimizing costs in any cutting…

Hypertherm plasma cutters are known for their high quality cuts. However, there are a few common problems that can occur…

Work with us today

For more information on our products, services, and solutions, and to get pricing, please click on the button below.