TEST 1:

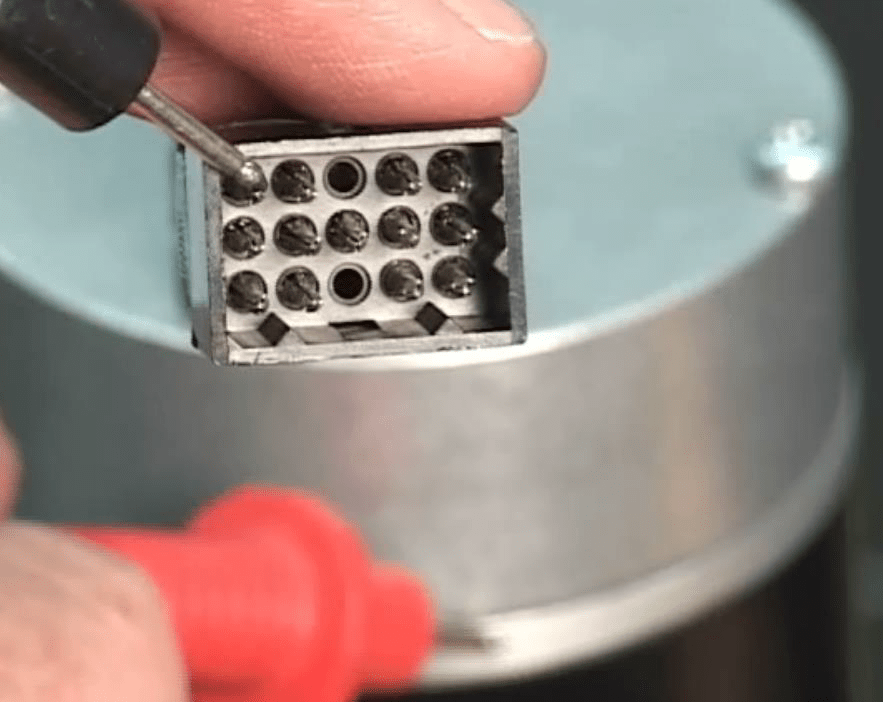

Measure the motor resistance through these two terminals on the motor wiring harness. The resistance should measure between 30 and 40 ohms.

Move the carriage or gantry by hand about 1/16 inch (1.6 mm) and repeat the measurement. (Ignore any readings you may get while moving the motor.) Keep moving by equal steps and measuring, until you have taken at least 16 measurements within 1 inch (26 mm) of travel.

TEST 2:

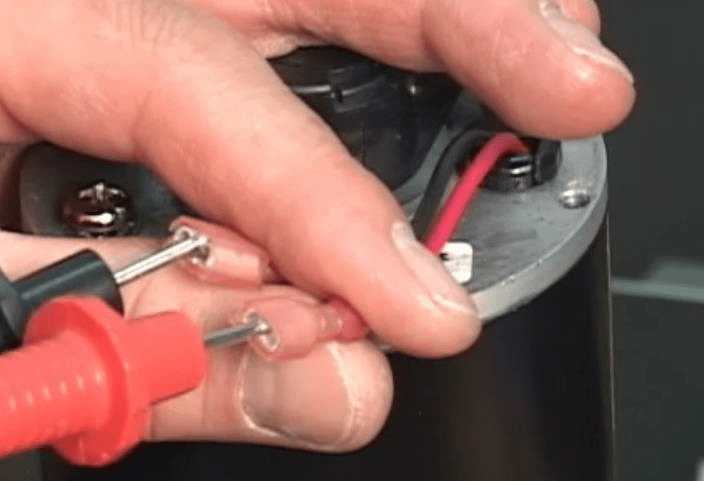

Verify isolation between this terminal and the bare metal end of the motor. Hold the probes in contact and push the carriage or gantry slowly through at least 1 inch (26 mm) of travel while measuring for isolation.

TEST 3:

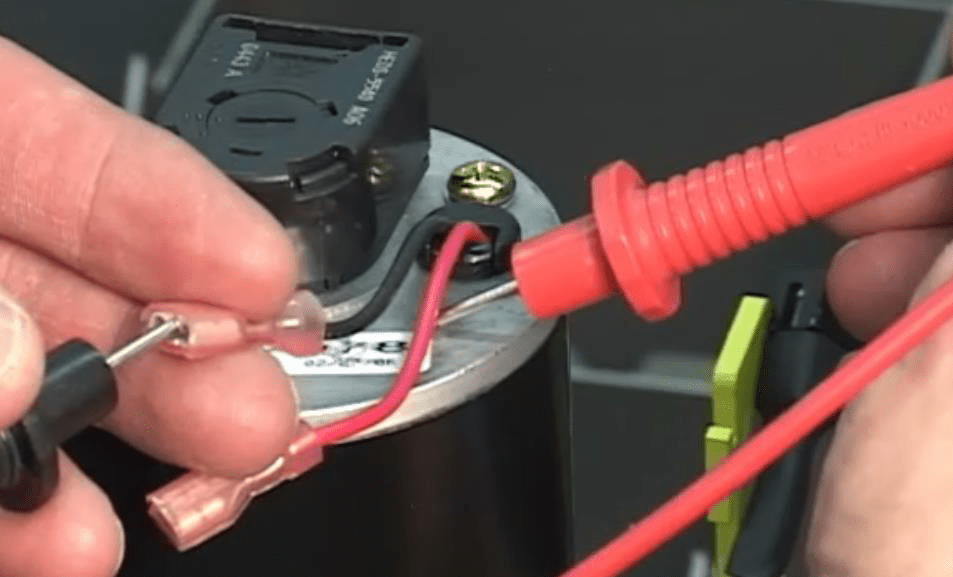

Verify continuity between this terminal and the bare metal end of the motor.

If the winding resistance, isolation and continuity tests always measure correctly, skip the remaining tests.

TEST 4:

Remove the wiring harness from the motor and repeat the resistance test by measuring between these two wires coming out of the motor.

TEST 5:

Repeat the isolation test by measuring between this wire and the bare metal end of the motor.

SUMMARY:

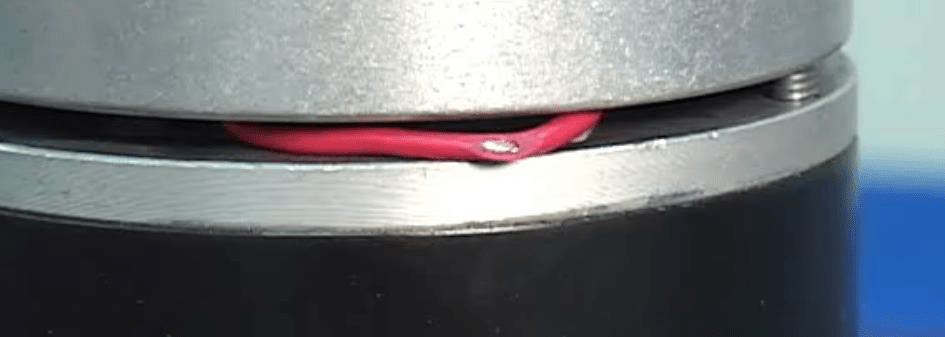

If either the resistance or isolation tests still fail, the carriage or gantry motor is faulty and should be replaced. Otherwise, the motor wiring harness is faulty and should be replaced. Note that a short circuit (isolation failure) could be caused by a motor wire being pinched under the cap during the installation of the cap.

Related Posts

How to relieve tension in the hose reel on a Dragon A400 Tube Cutting Plasma.

How often you need to change the consumables on your Powermax 45/65/85/105/125 will depend on a number of factors: •…

Ensure the black cable is connected to the UC100 and is plugged into the USB port on the computer. Also…

Work with us today

For more information on our products, services, and solutions, and to get pricing, please click on the button below.