Are you looking for a hobbyist plasma cutter for your hobbies or small workshop? Do you work with metal at home? A CNC machine is a powerful and efficient solution, enabling you to make cleaner, faster cuts with ease.

In this article, we cover the different types of CNC plasma machines available in Australia, focusing on hobby machines and entry-level machines.

WHAT IS A CNC PLASMA CUTTER?

A CNC plasma cutter is a thermal cutting tool used to cut metals, controlled by highly accurate and automated Computerised Numerical Control (CNC). The plasma torch conducts an electrical circuit, heating and melting the metal to produce a clean and precise cut.

Generally, plasma cutters are used in industrial manufacturing to cut through electrically conductive metals, such as steel, aluminium, stainless, brass, and copper.

Key benefits include:

- Safety and automation

- Speed and efficiency

- Ease of use

- Versatility

- Precision

BEST HOBBY CNC PLASMA CUTTERS IN AUSTRALIA

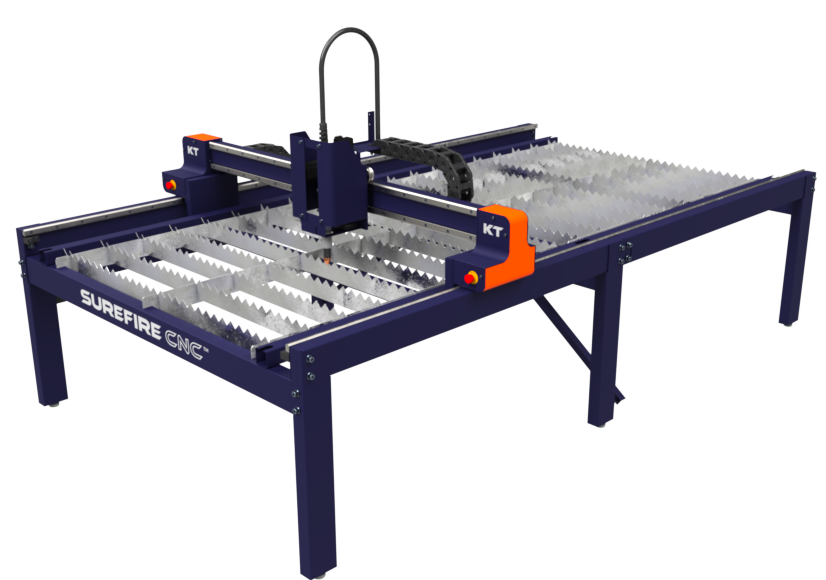

If you work on a lot of DIY projects or work in an educational facility, you might benefit from a small plasma-cutting machine. Our new KT Series are perfect for DIYers and beginners. Unlike the industrial XT Series, our KT Series plasma cutters are designed with a minimalist design, making them ideal for hobbyists.

KT SERIES

With a KT Series table, you don’t need to be a millionaire to design and cut metal parts in your workshop. Whether you’re an amateur CNC user or a long-time enthusiast, the KT tables will help you take control of your projects.

The KT Series is the perfect ‘no-frills’ investment for your small to medium workshop. This series has been carefully designed from the ground up by Australian industry experts and engineers, with contributions from CNC plasma operators all over the country.

- Can be extended in the future to keep up with production requirements

- Easy to operate and maintain

- Cost-effective

- Safe

- Lightweight and portable

- Backed up with local Australian technical support

- Available as a customised CNC package, including a plasma cutter, software, and a full suite of accessories.

These machines were developed to meet the needs of Aussie and New Zealand metal workers who need a unit that is compact, durable, easy to operate, backed by local technical support, and cost-effective. The KT Series tables are available in two sizes, including:

KT12

The KT12 is small entry-level cutter with a 1220mm by 1220mm cutting area. Designed for small spaces. The machine measures 1,850mm wide by 1,550mm long and 1,450mm high. The steel table construction is durable and low maintenance while the stainless steel waterbed offers cost-effective fume control and reduces warpage.

SPECIFICATIONS

- Plasma power-source options — Up to 20mm steel capacity

- Travel Speed — Up to 10,000mm/min

- Drive System X + Y Axis — Precision ‘V’ guideway rack & pinion, twin gantry motors

- Drive System Z Axis — Precision ball & screw

- Input Power — 240V 10 Amp

Depending on the plasma option, prices for the KT12 start from $19,900 or $19/day on finance.

KT24

The KT24 has a cutting area of 1220mm by 2420mm, suited to full-size 4ft by 8ft sheets. Designed for small spaces, the machine measures 1,850mm wide by 3,050mm long and 1,450mm high. The steel table construction is durable and low maintenance while the stainless steel waterbed offers cost-effective fume control and reduces warpage.

SPECIFICATIONS

- Plasma power-source options — Up to 20mm steel capacity

- Travel Speed — Up to 10,000mm/min

- Drive System X + Y Axis — Precision ‘V’ guideway rack & pinion, twin gantry motors

- Drive System Z Axis — Precision ball & screw

- Input Power — 240V 10 Amp

Depending on the plasma option, prices for the KT24 start from $24,900 or $22/day on finance.

Take control of your home DIY metal components & artworks

With an “in-house” CNC plasma cutting table, you can cut what you want, when you want… instead of waiting for a contractor to do it in their time, not yours.

At SUREFIRE CNC, we offer a range of CNC plasma cutting tables to match your specific needs. Our XT Series & KT Series (coming soon) CNC Plasma table kits, are supplied in flat-pack form which means we are able to deliver direct cost savings to you, without sacrificing functionality and quality. Furthermore, the convenience of a flat-pack design means you can set the CNC cutter up in the smallest of home garages without being restricted by the door opening!

FAQs

I have space constraints, how physically big are the tables?

A picture paints a thousand words, check out this setup where one of our customers setup a fullsize CNC Plasma package inside a shipping container on his farm!

What tolerances can be achieved with a home hobby CNC Plasma?

The SUREFIRE CNC machines come with preset factory settings, designed to achieve accuracies ranging from 0.3mm to 0.8mm. However, it’s important to note that the remaining level of inaccuracy can be attributed to the kerf of your plasma cutter consumables. Generally speaking, we advise customers to allow at least a 1mm tolerance.

What warranty do you offer?

At SUREFIRE CNC, we stand behind the quality of our products. As part of our commitment to customer satisfaction, we offer a generous 12-month warranty on all mechanical and controller parts of most SUREFIRE CNC Plasma systems. This warranty covers any manufacturing defects or malfunctions that may occur during normal use. During the warranty period, we are here to support you with technical assistance for any issues you encounter with your SUREFIRE CNC Plasma. Whether you have questions about its functionality, troubleshooting concerns, or need guidance on achieving the desired cutting results, our knowledgeable support team is ready to assist you. Rest assured that if any of the covered parts fail within the warranty period, we will provide you with replacement parts at no additional cost. We want to ensure that you have a seamless experience with our product, and our warranty is designed to give you peace of mind. To initiate a warranty claim or seek support, we recommend reaching out to us via convenient communication channels such as Whatsapp, SMS, or Facebook messenger. These platforms allow us to easily exchange information and photos, if needed, to better understand and address your specific situation. Your satisfaction is our top priority, and we are committed to providing you with exceptional customer service throughout the warranty period and beyond.

What issues may arise if the right plasma cutter, power supply, or air supply is not used?

If the right plasma cutter, power supply, or air supply is not used, several issues may arise:

1. Poor cut quality: Using an inadequate plasma cutter, power supply, or air supply can result in various problems such as serrations, gagged edges, or bevelled cuts. These issues not only compromise the appearance of the cut but also affect its precision and accuracy.

2. Dross accumulation: Insufficient or improper equipment can lead to the buildup of slag, known as dross, at the top or bottom of the material being cut. This can occur due to factors such as incorrect feed speed, distance, worn consumables, incorrect air pressure, or suboptimal plasma cutter settings.

3. Incomplete cutting: When using the wrong plasma cutter, power supply, or air supply, you may encounter incomplete cuts where certain spots are missed. This can be caused by dirty air, excessive feed speed, or inadequate amperage.

4. Plasma cutter malfunctions: If the plasma cutter, power supply, or air supply is not suitable for the task at hand, the equipment may frequently stop operating. This can occur either due to the duty cycle being reached (exceeding the recommended usage time) or the breaker tripping, resulting in interruptions during the cutting process.

To ensure optimal results and avoid these issues, it is essential to use the appropriate plasma cutter, power supply, and air supply for the specific application.

What power supply and air supply setup is needed?

To ensure optimal performance and safety while using a plasma cutter, it is important to consider the power supply and air supply setup. Here are some key points to keep in mind:

Power Supply:

1. Duty Cycle and Breaker Capacity: Determine the power requirements of your plasma cutter and ensure that your breaker can safely handle it. For example, if your plasma cutter has a 10A power supply plug, make sure that your breaker can handle this load without tripping during the duty cycle. 2. Consult an Electrician: If there is a possibility that your plasma cutter’s power requirements may exceed the capacity of your existing GPOs (General Power Outlets) or breakers, it is strongly recommended to consult an electrician. They can assess your electrical system and advise on any necessary upgrades to safely accommodate the plasma cutter.

3. Separate Breaker for Plasma Cutter: To prevent any interference or power disruptions, it is advised to operate the plasma cutter on a separate breaker. This is particularly crucial if you are using other appliances simultaneously, such as a computer. By avoiding power loss to the computer, you can easily resume your work without any complications.

Air Supply:

1. Adequate Air Requirements: Read the requirements specified by your plasma cutter manufacturer and ensure that your compressor provides a clean and regular air supply meeting the minimum required. It is also recommended to have some additional capacity to spare.

2. Moisture Control: To prevent damage and ensure the longevity of your plasma cutter, it is highly recommended to use an air filter or equivalent device such as a Z-20 air filter. These types of filters are designed to collect and remove moisture from the air supply, ensuring a cleaner and drier air flow. Consider investing in an air dryer for even better moisture control.

By paying attention to these considerations, you can create a suitable power supply and air supply setup for your plasma cutter, allowing for efficient operation and minimizing the risk of any electrical or air-related issues.

What are the advantages of SUREFIRE CNC Plasma Tables?

The SUREFIRE CNC table range offers several advantages that elevate your project capabilities to new heights in terms of speed, convenience, and precision. Unlike expensive industrial CNC machines that cost between $80k-$100k, the SUREFIRE CNC XT series for example, provides similar performance but at a fraction of the price.

By incorporating helical rack and pinion and linear rails, this machine competes strongly against imported machines. Its advanced features enable you to achieve accurate results with ease and efficiency.

The SUREFIRE CNC tables offer numerous advantages, including affordability, impressive performance comparable to high-end CNC machines, and user-friendly software.

Can the CNC machine be shipped interstate?

Yes, the CNC machine can be shipped interstate. There are several shipping options available for customers who are located outside of the immediate area. The options include organising shipping at an additional cost, direct delivery to a residential address with a forklift or crane, direct delivery to a business address with a forklift, pick up from a transport depot (which may require organising your own transport from the depot), or organizing your own courier service. These options provide flexibility for customers located interstate to receive their SUREFIRE CNC machine safely and conveniently.

What materials can a plasma cutter cut?

A plasma cutter is capable of cutting a variety of materials. Some of the most common materials that can be effectively cut using a plasma cutter include mild steel, stainless steel, aluminum (with necessary precautions for fumes), and brass. It’s important to note that a plasma cutter can cut virtually anything that is conductive. Thus, it offers a wide range of possibilities for cutting through different types of metals and conductive materials.

Related Posts

Not all CNC plasma cutters are built the same. Choosing the wrong machine can cost you time, money, and plenty…

CNC plasma cutting is a fast, precise, and efficient cutting method. While it is straightforward and efficient to use, it…

CNC Plasma cutting machines are a great way to improve the efficiency and quality of your metalwork but sometimes things…

Work with us today

For more information on our products, services, and solutions, and to get pricing, please click on the button below.