Performance and Features

- Material Compatibility: Handle a wide range of electrically conductive materials, including steel, aluminium, brass, and titanium.

- Equipment Compatibility: Integrate seamlessly with most CAD software programs. They also include a simple 2D CAD program for beginners and a user-friendly SureControl™ software interface.

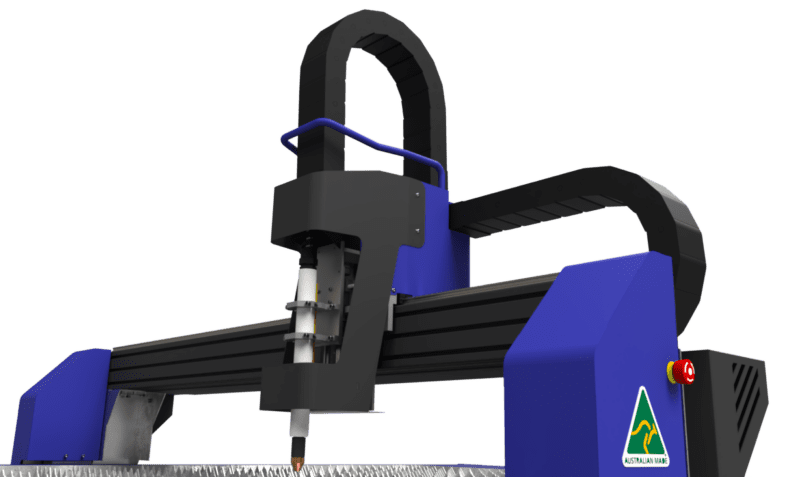

- Automated Height Control: The machines feature automated torch height control (THC), ensuring precise cuts on uneven or thin materials prone to warping.

- Software and Usability: The SureControl™ software, included with every package, is intuitive and efficient. It eliminates the need for complex G-code knowledge and includes pre-loaded cut settings for faster setup.

- Cutting Accuracy and Precision: Using a direct rack and pinion drive mechanism combined with precision linear bearings, the machines achieve cutting accuracy within 0.1mm. This ensures consistent, high-quality cuts for intricate designs.

- Cutting Speed and Capability: Travel speeds of up to 10,000mm per minute, providing efficient operation for both thin and thick materials.

Quality Support and Operations

- Delivery and Setup: Our machines are shipped flat-packed in a sturdy timber crate with a comprehensive setup guide. Virtual support is available for assembly, and installation assistance can be arranged.

- Training and Documentation: Each system includes detailed user manuals and training options.

- Maintenance and Parts Availability: Readily available replacement parts and consumables. Features like SYNC™ cartridges ensure consumables are used efficiently, reducing waste and costs.

- Technical Support and Assistance: Surefire provides comprehensive support, including troubleshooting and remote assistance. Customers can request on-demand help or installation services if needed.

Made and perfected in Australia

We firmly believe that Australian manufacturing is right up there with the best. And that’s why our range of CNC Plasma Cutters are designed and made right here in Australia.

In addition, SUREFIRE partners with other leading manufacturers globally – such as Hypertherm, to develop equipment solutions that deliver what Aussie fabricators are looking for.

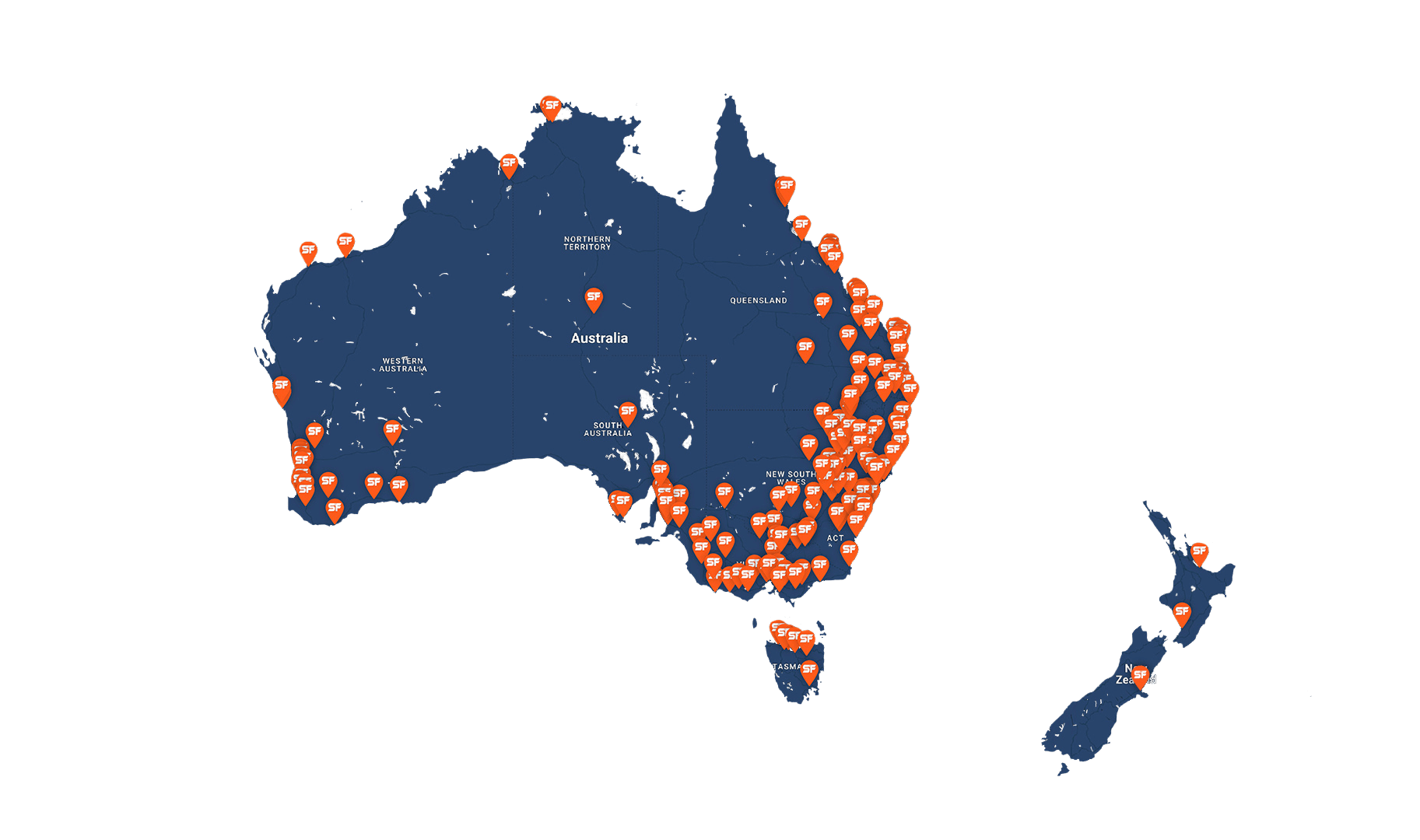

Trusted By

Providing support to our clients

- What materials can I cut?

Plasma will cut any electrically-conductive materials, including steel, stainless-steel, aluminium and most metals. Our tables are used for a wide range of metal fab applications where versatility is critical, such as fabrication shops, manufacturing, automotive repair and restoration, training centres, and more.

- How does a CNC plasma table work?

In short, a plasma table is the main component in a CNC cutting system used for shaping flat sheets of steel or metal. To perform this task, a plasma table must be coupled with other machinery. The main components of a plasma-table system and their functions are as follows;

- Table: Supports the sheet or plate and may include features such as a water bed.

- Gantry: Mounted on the table; carries and moves the torch. Its position is driven by the controller along the X- and Y-axes.

- Plasma torch: Fixed to the gantry; performs the actual cut. Compressed air passes through the nozzle, an electric arc creates ionised gas (plasma), and the jet pierces the metal.

- Power source: Supplies current to the torch.

- Air compressor / air supply: Feeds pressurised air to the cutter and torch.

- Computer system: A PC and display that host the operating software.

- Software: Handles design (CAD), file preparation (CAM), and motion control (CNC). Drawings can also be imported from other machines or files.

- What is a CNC plasma table used for?

CNC Plasma tables are used in metal fabrication and manufacturing industries for cutting components from flat metal sheet or plate, including steel, stainless-steel, aluminium & other metals.

- How accurate is CNC plasma?

This depends on a few factors. First the design of the table; XT Series are accurate to within 0.2mm, thanks to the direct rack & pinion drive mechanism. Next is the accuracy of the plasma arc, which will vary depending on the quality and condition of the system, torch and consumable parts. We recommend allowing between 0.5-1.0mm for arc deviation, noting that worn consumables and poor air quality will result in higher deviation. One of the reasons we use Hypertherm is because they offer unmatched performance, accuracy and parts durability.

- Should I consider CNC Laser, Waterjet or Oxy?

Great question! Each system has their place. For general metalfab applications with materials of up between 1mm & 30mm thickness, CNC Plasma offers the best combination of affordability, fast cutting (productivity), low running costs and versatility. For more information on this topic, visit our blog Plasma vs Waterjet vs Laser vs Oxy | How Economical is CNC Plasma?

Your Experienced Team

SUREFIRE CNC Plasma machines sold